Series and Parallel Pipe Systems

In hydraulic engineering, pipe networks rarely consist of single, uniform pipes. Instead, real-world systems involve complex arrangements of pipes with varying diameters, lengths, and materials. Understanding how these pipes interact when connected is fundamental to designing efficient water supply systems, analyzing flow distribution, and predicting pressure losses throughout the network.

Bernoulli’s Equation (Energy Equation)

![]()

where:![]()

![]()

![]()

![]()

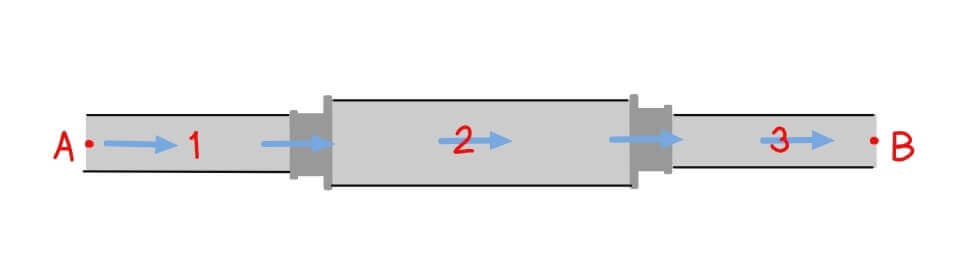

Series Pipe System

Series pipe systems consist of pipes connected end-to-end in a sequential arrangement. In this configuration, fluid flows through one pipe section before entering the next, creating a continuous flow path from inlet to outlet.

![]()

Head Loss

![]()

Key Characteristics

- Same volumetric flow rate (Q) passes through each pipe section

- Total Head Loss equals the sum of individual head losses in each pipe

- Different pipe diameters have different velocities each section

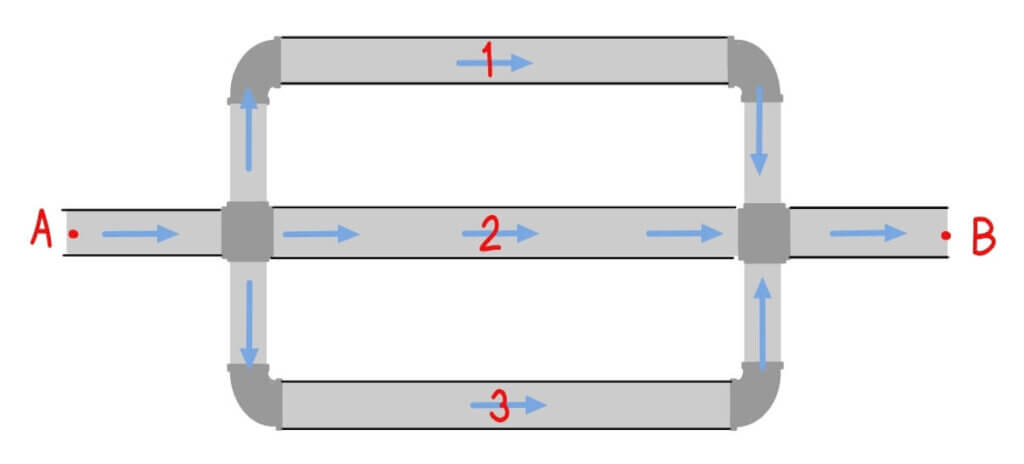

Parallel Pipe System

![]()

Head Loss

![]()

Key Characteristic

- Flow divides among the parallel branches

- Head loss is identical across all parallel paths

- Each branch can have different diameters, lengths and roughness coefficients

Fundamental Energy Principle

In analysis of series and parallel pipe systems, we based it using Bernoulli’s Equation (Energy Equation), which describes the conservation of energy in flowing fluids. Between any two points in a pipe system:

![]()

where:

P/γ = pressure head

V²/2g = velocity head

z = elevation head

hf = friction head loss

hm = minor head losses

Friction Loss Equations (Velocity Form)

Friction loss is the energy dissipated due to fluid friction with pipe walls. Several empirical formulas are commonly used to calculate friction losses in pipe systems.

Here are the examples of common derived friction loss.

Darcy-Weisbach Formula

The most fundamental and universally applicable friction loss equation:

![]()

where:

hf = friction head loss (m)

f = Darcy friction factor (dimensionless)

L = pipe length (m)

D = pipe diameter (m)

V = flow velocity (m/s)

g = gravitational acceleration (9.81 m/s²)

Manning’s Equation

Commonly used for gravity flow in pipes and open channels:

![]()

where:

V = average velocity (m/s)

R = hydraulic radius (m)

S = energy slope (m/m)

n = manning’s roughness coefficient

Friction Loss (Discharge Form)

Darcy-Weisbach Formula

![]()

Where:

Q = discharge (m³/s)

Manning’s Formula

![]()

Where:

n = Manning’s roughness coefficient

Q = discharge (m³/s)

L = pipe length (m)

D = pipe diameter (m)

Hazen-Williams Formula

Mostly used for water distribution systems:

![]()

Where:

hf = friction head loss (m)

L = pipe length (m)

Q = discharge (m³/s)

C = Hazen-Williams coefficient (typical values: 100-150)

D = pipe diameter (m)

Practical Design Examples

Consider a municipal water distribution system:

- Main Transmission Line (Series) – They are large diameter pipes usually from water treatment facilities to the cities (include pictures)

- Distribution Grid (Parallel Loops) – Multiple pathways. There are several options in a city which engineers consider.

- Service Connections (Series Branches) – Smaller pipes to individual properties.

Real World Complexity

Most hydraulic systems combine both series and parallel arrangements because of practicality and complexity of some area. These branched networks require systematic analysis methods to determine flow distribution and pressure drops throughout the system.

Analysis Methods

1. Hardy Cross Method

An iterative technique that balances flow and head loss in looped networks through successive approximations.

2. Node-Flow Method

Establishes flow continuity equations at each junction node and solves simultaneously for unknown flows.

3. Loop-Flow Method

Applies energy balance equations around closed loops within the network.

4. Computer Modeling

Modern software packages like EPANET, WaterCAD, and similar tools use sophisticated algorithms to solve large network systems efficiently.

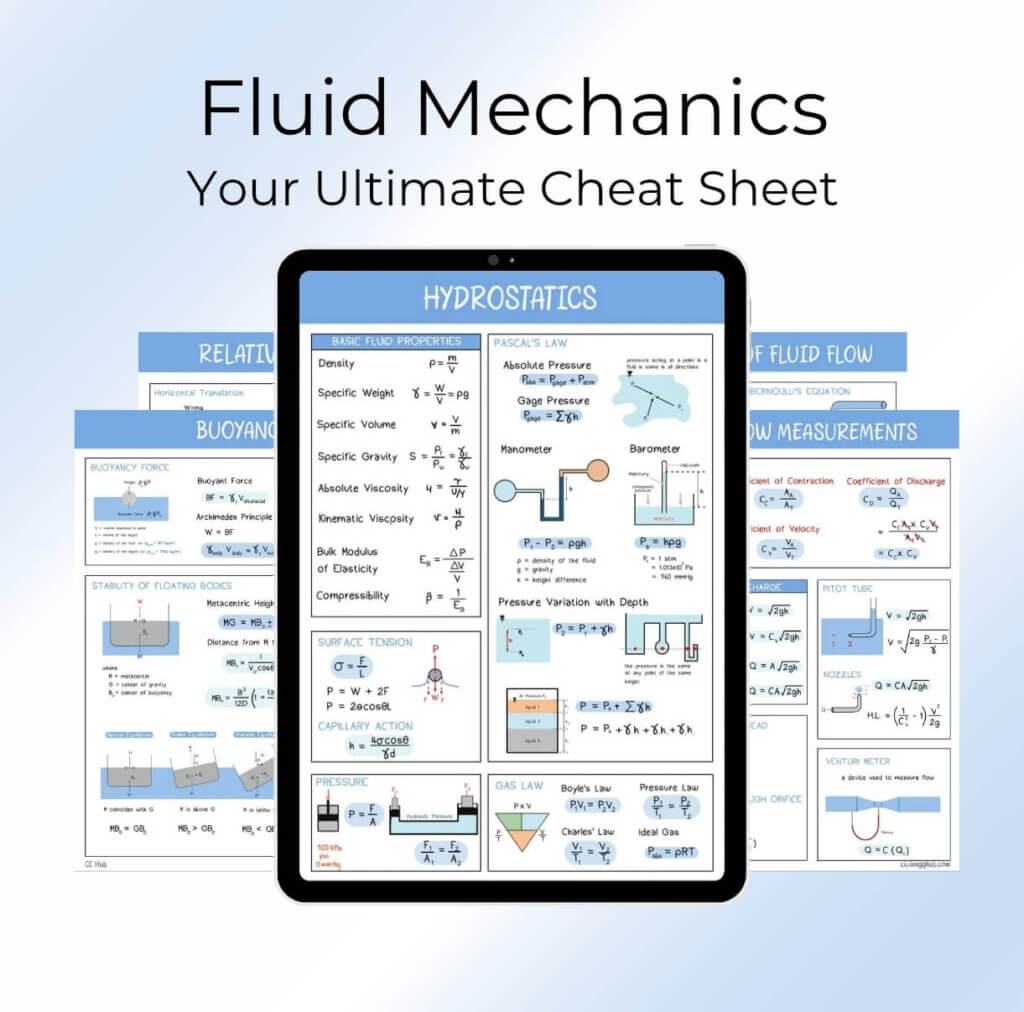

📍This post is part of FLUID MECHANICS COMPLETE Lessons. Also, if you want to avail the complete Cheat Sheet just click the ‘IMAGE” below.