Pile Capacity in Geotechnical Engineering

What are Piles and When to use them?

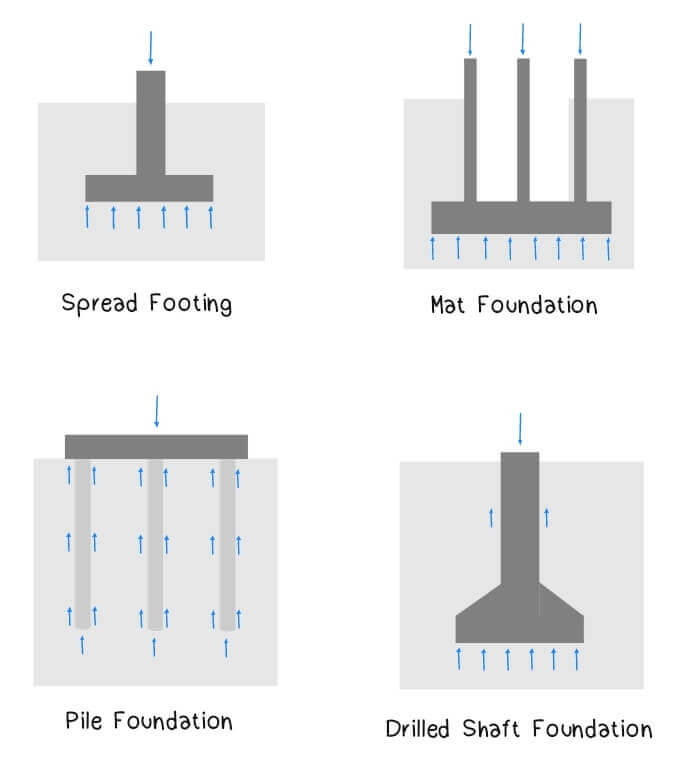

Piles are structural members made of steel, concrete, or timber that serve as deep foundations where the depth or length is significantly larger than the width. Unlike shallow foundations, deep foundations require special equipment and skilled labor, making them more expensive than conventional spread footings.

When are Pile Foundation recommended?

There are different types of foundation. Pile foundation should be considered when shallow foundations prove inadequate.

- Weak Ground Conditions

- Cannot withstand the heavy load from the structure

- Resisting Uplift

- Compaction Piles

Types of Pile Foundation

- Steel Pile

- Concrete Pile

What is Pile Capacity?

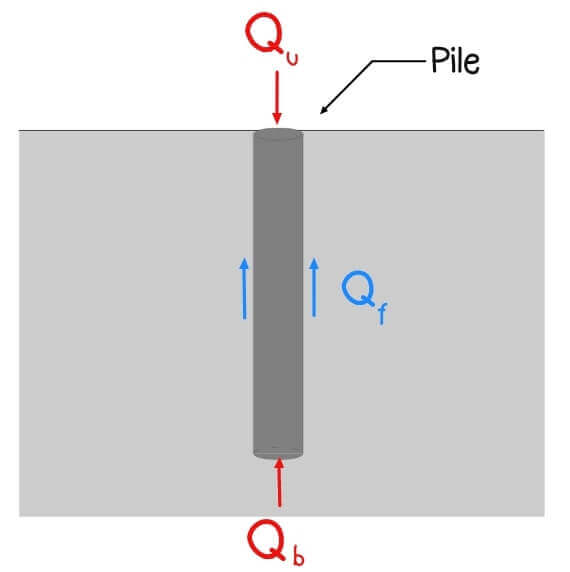

Pile capacity refers to the maximum load a pile can safely support without experiencing excessive settlement or structural failure. It encompasses two critical components:

Ultimate Pile Capacity (Qu)

The maximum load the pile can sustain before failure occurs, combining both shaft resistance and end-bearing capacity.

The ultimate load carrying capacity (Qu) of a pile is given by the fundamental equation:

![]()

where:![]()

![]()

![]()

Allowable Load Capacity (Qa)

The safe working load obtained by dividing the ultimate capacity by an appropriate factor of safety, typically ranging from 2.0 to 3.0.

The allowable load capacity provided a safety margin against failure:

![]()

where:![]()

![]()

Component of Pile Capacity

1. Shaft Resistance (Skin Friction)

Shaft resistance develops along the embedded length of the pile through friction and adhesion between the pile surface and surrounding soil.

2. End Bearing Capacity

End bearing resistance occurs at the pile tip, where the load is transferred directly to the bearing stratum. This component becomes dominant when:

- Piles are driven to hard rock or dense soil layers

- The pile diameter is relatively large

- Using short, stubby piles

Piles on Sand

End-Bearing Capacity

![]()

where:

![]()

![]()

![]()

Skin Friction Resistance

![]()

where: ![]()

![]()

![]()

![]()

Piles on Clay

![]()

![]()

Alpha Method

The ![]() method is widely used for cohesive soils in undrained conditions:

method is widely used for cohesive soils in undrained conditions:

CLAP

![]()

where: ![]()

![]()

![]()

![]()

Beta Method

BLOP

![]()

where:![]()

![]()

![]()

![]()

![]()

Lambda Method

![]()

where:![]()

![]()

![]()

![]()

![]()

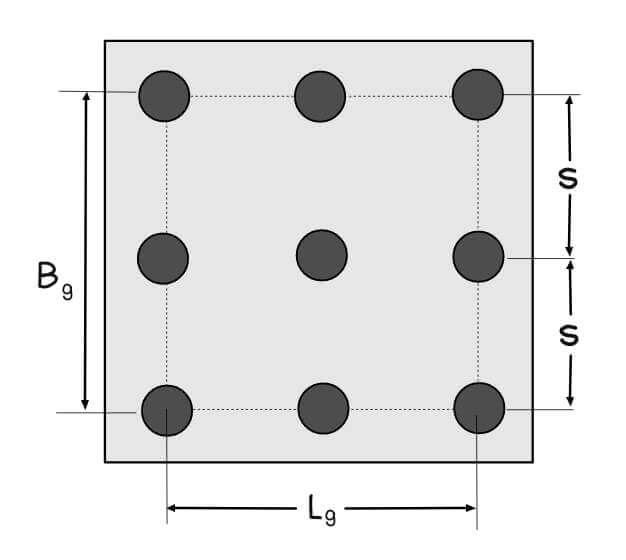

Pile Act as a Block

When multiple piles are installed close together, they don’t simply act as independent load-bearing elements. Instead, the soil zone around and beneath the pile group becomes stressed as a single unit.

![]()

End Bearing Capacity

![]()

Skin Friction

![]()

Group Efficiency

Converse-Labarre Equation

![]()

Bowles Equation

![]()

where:

![]()

![]()

![]()

![]()

![]()

References:

Das, B.M. (2007). Principles of Foundation Engineering (7th Edition). Global Engineering

Rajapakse, R. (2016). Pile Design and Construction Rule of Thumb (2nd Edition). Elsevier Inc.

Tomlinson, M.J. (2004). Pile Design and Construction Practice (4th Edition). E & FN Spon.