Thermal Deformation and Thermal Stress

What is Thermal Deformation?

BY DEFINITION

Thermal deformation is the change in dimensions of a material when it experiences a temperature change. Think of it as materials as a reaction in response to heat or cold.

Note: When temperature increases, materials expand (lengthening). When temperature decreases, materials contract (shortening).

Thermal effects can become a serious safety issue for structures. There are cases in Austria and Italy where cantilevered bridges collapsed during construction because temperature-induced stresses were not adequately accounted for (Heckel, 1971). Though now, this type of behavior is predictable and can be quantified, which is exactly what makes it manageable in engineering design. That is why bridges are detailed with small gaps that allow for thermal expansion and contraction.

Thermal Deformation vs. Thermal Stress

Thermal Deformation occurs when a material is free to expand or contract due to temperature changes.

- The material is in a stress-free state

- The material changes length

- No internal stress is developed

Thermal Stress occurs when a material is restrained or prevented from deforming due to temperature changes. In this case:

- The material cannot change length freely

- Internal stresses develop

- These stresses can be significant and must be accounted for in design

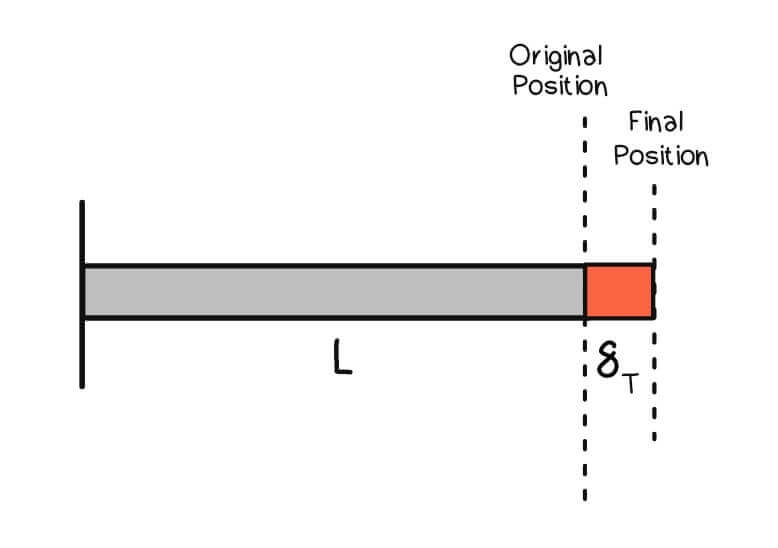

Thermal Deformation Equation

![]()

Where:

δ_T = Thermal deformation (change in length)

α = Coefficient of thermal expansion

L = Original length of the member

ΔT = Change in temperature

Note:

Positive δ_T → Expansion (lengthening)

Negative δ_T → Contraction (shortening)

Thermal Strain Equation

Strain as we all know, is the deformation per unit length. With this, we can formulate the formula:

![]()

This formula reveals an important insight: thermal strain depends only on the material property (α) and the temperature change (ΔT). This is fundamentally different from mechanical strain, which depends on the applied stress and material stiffness.

Table: Common Coefficients Thermal Expansion for Materials

| Material | Coefficient α (× 10⁻⁶ /°C) | Coefficient α (× 10⁻⁶ /°F) |

| Steel | 11.7 | 6.5 |

| Aluminum | 23.0 | 12.8 |

| Concrete | 9.9 | 5.5 |

| Copper | 16.5 | 9.2 |

The Connection between Thermal Effects and Mechanical Stress-Strain

We’ve learned that stress and strain are related in strength of materials.

![]()

This is Hooke’s Law—the foundation of elastic analysis. But what happens when we combine thermal effects with mechanical loading?

Summary and Key Takeaways

The fundamental formula:

![]()

Key principles:

- Materials expand when heated, contract when cooled

- Free deformation → no stress

- Restrained deformation → thermal stress develops

- Different materials have different thermal expansion coefficients

References

Beer, F. P., Johnston, E. R., DeWolf, J. T., & Mazurek, D. F. (2020). Mechanics of materials (8th ed.). McGraw-Hill Education.

Gere, J. M., & Goodno, B. J. (2017). Mechanics of materials (9th ed.). Cengage Learning.

Hibbeler, R. C. (2018). Mechanics of materials (10th ed.). Pearson Education.

Pytel, A., Kiusalaas, J., & Singer, F. L. (2013). Strength of materials (4th ed.). Springer.