SIMPLE STRESS

What you’ll learn

- The meaning of simple stress and why it’s a foundational concept in Strength of Materials

- Different types of Stress like Normal Stress, Shear Stress and Bearing Stress

- How will structural elements—like beams, rods, and columns—respond to applied forces?

In Strength of Materials, one of the key concepts to grasp is simple stress—the fundamental internal resistance that a material develops when subjected to external forces. Whether it’s a beam, rod, or column, understanding stress is essential to ensuring that structures can carry loads safely without failure.

What is Stress?

Stress refers to the force applied per unit area of a material. It represents the internal resistance that develops when an object is subjected to external loads. The general formula for stress is:

where:

= Stress (N/m² or Pascals)

F = Applied force

A = Cross-Sectional area

Stress is categorized into three types:

- Normal Stress

- Shear Stress

- Bearing Stress

1. Normal Stress

Normal Stress is either Tensile Stress or Compressive Stress.

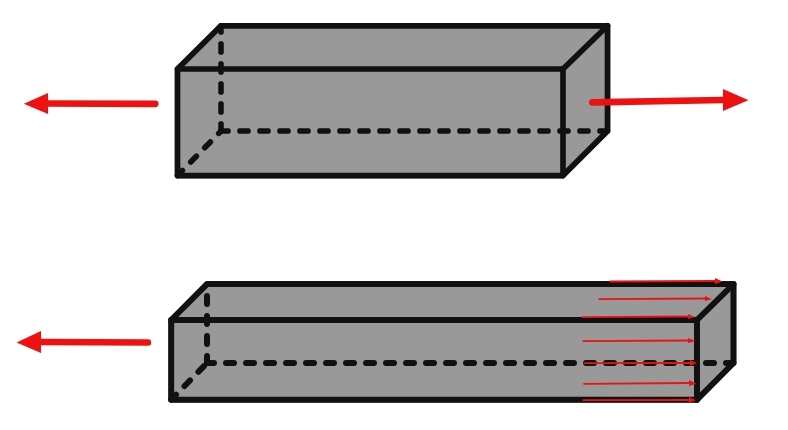

Tensile Stress

Tensile stress occurs when a material is subjected to a pulling force, responsible for the elongation of the material. Imagine pulling a rubber band from both ends — it becomes longer and thinner. The same principle applies to materials like steel and concrete, which experience great tensile stress in structural construction.

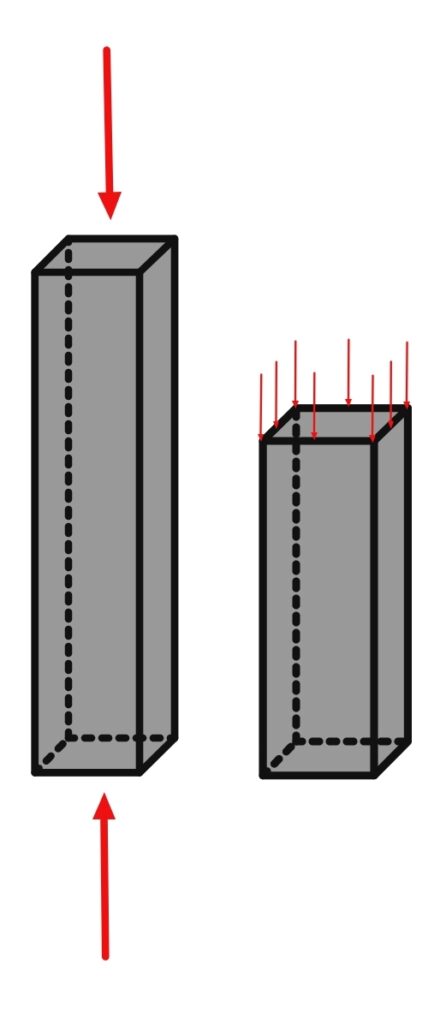

Compressive Stress

Compressive stress happens when a material is subjected to a pushing force, responsible for shortening of the material.

2. Shear Stress

Arises when forces act parallel to the material’s surface, causing it to slide.

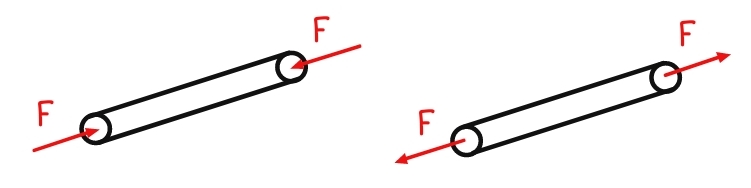

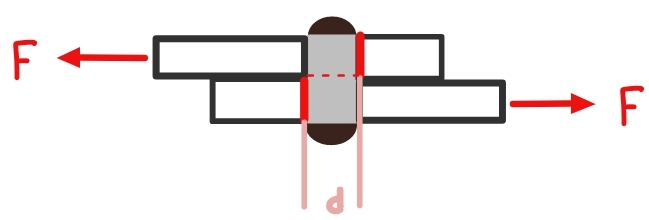

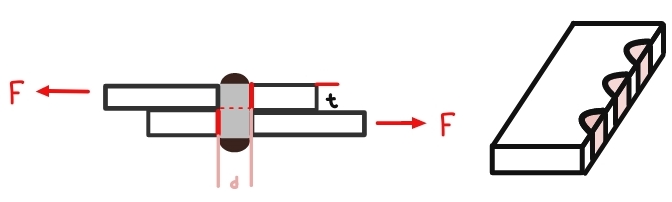

Single Shear

Single shear occurs when a structural member or fastener experiences a shear force that causes failure along a single plane. This is commonly seen in bolted or riveted connections, where the applied force tries to slide one section of the material past another along a single cross-section.

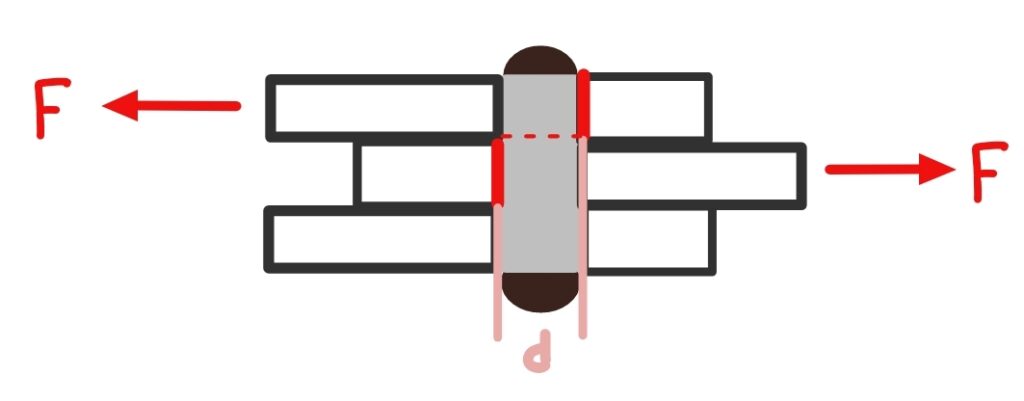

Double Shear

Double shear occurs when a structural member or fastener is subjected to shear forces that cause failure along two parallel planes. Compared to single shear, it offers greater resistance to failure since the applied force is distributed across two surfaces, reducing the stress on each plane.

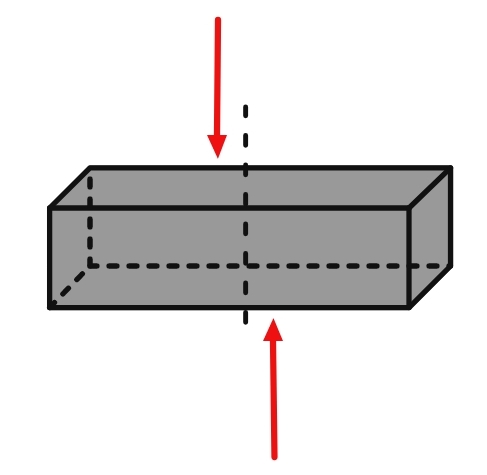

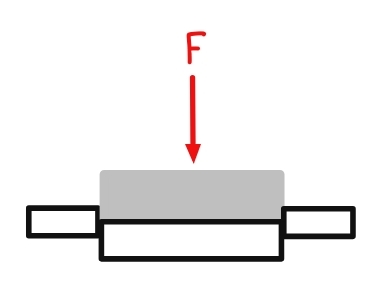

Punching Shear

Punching shear is a localized shear failure that occurs when a concentrated load is applied to a small area of a structural member, causing the material to be punched through. This type of failure is commonly seen in slab-column connections and footings under column loads, where high stresses develop around the loaded area.

3. Bearing Stress

Bearing stress occurs when a load is transmitted between two contacting surfaces, causing compressive stress at the interface. It is commonly seen in bolted, riveted, or pinned connections, where the applied force presses one material against another.

EXAMPLE 1.0

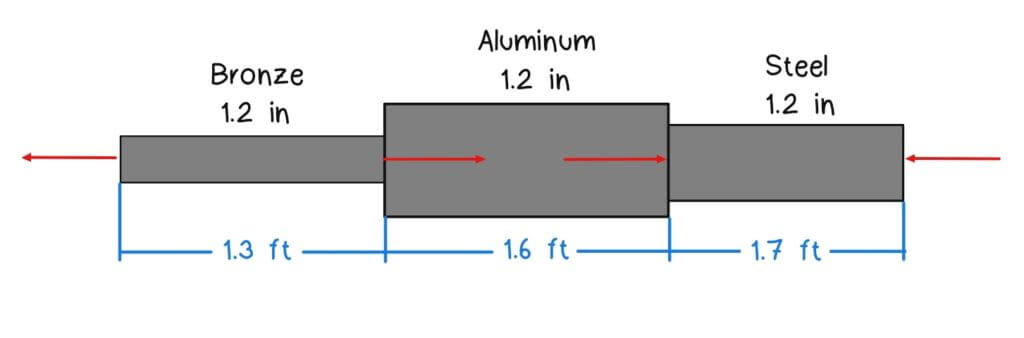

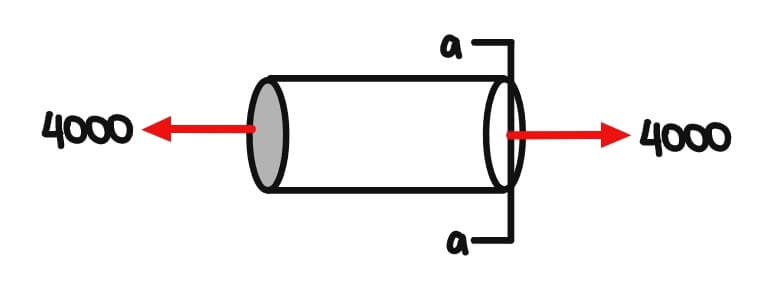

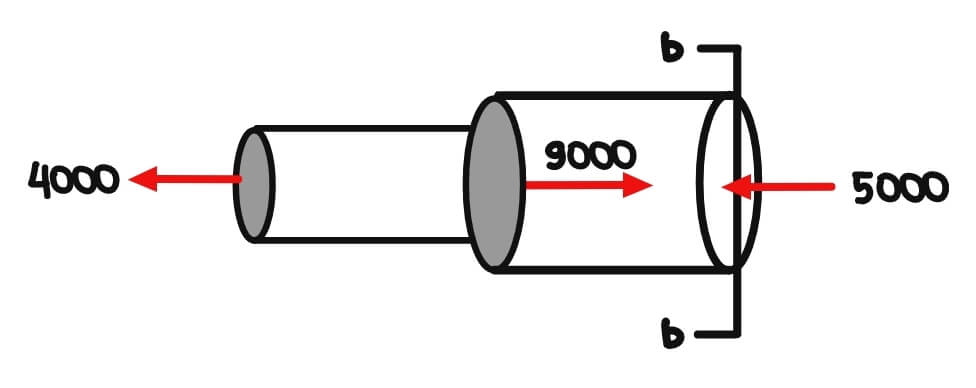

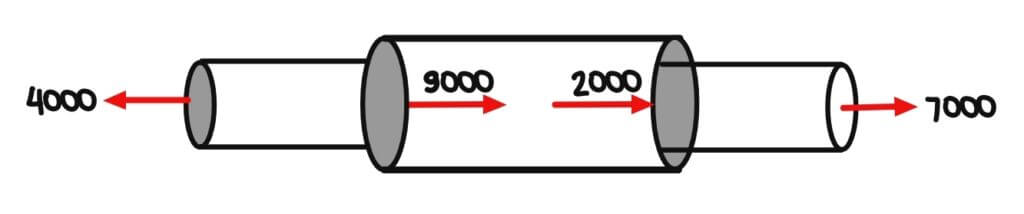

1. A composite bar consists of an aluminum section rigidly fastened between a bronze section and a a steel as shown. Axial loads are applied at the positions indicated. Determine the stress in each section.

EXAMPLE 2.0

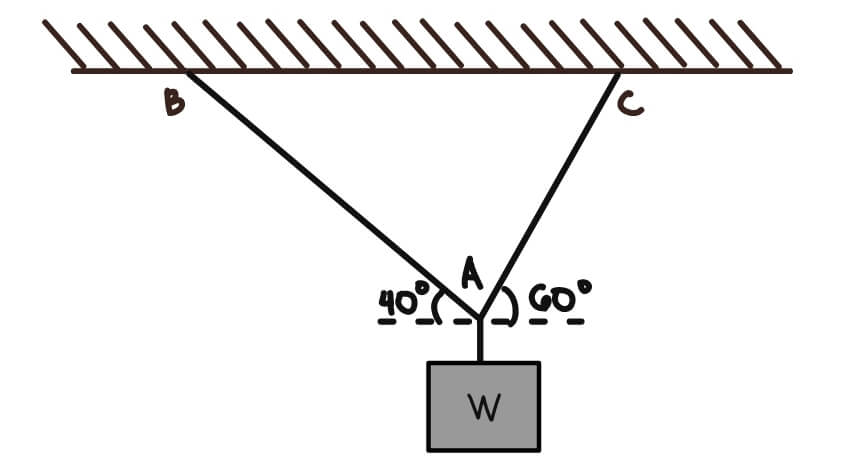

2. The block of weight W in the figure hangs from the pin at A. The bars AB and AC are pinned to the support B and C. The areas are ![]() for AB and

for AB and ![]() for AC. Neglect the weights of the bars, determine the maximum safe value of W if the stress in AB is limited to 110 MPa and that in AC is limited to 120 MPa.

for AC. Neglect the weights of the bars, determine the maximum safe value of W if the stress in AB is limited to 110 MPa and that in AC is limited to 120 MPa.

First equation, derived from Fx:

Second equation, derived from Fy:

Equating first and second equation:

The maximum safe value of W is the smaller one, 61.7 kN.

References

Beer, F. P., Jr, R., Dewolf, J. T., & Mazurek, D. F. (2020). Mechanics of materials. Mcgraw-Hill Education, © C.

Shear Stress and Shear Strain. (n.d.). https://www.purdue.edu/freeform/me323/wp-content/uploads/sites/2/2022/01/03_shear_stress_strain.pdf