Water Distribution Systems

A water distribution system is the network of pipelines, storage facilities, and appurtenances that delivers treated water from the source to consumers. The configuration and layout of this network significantly impact its efficiency, reliability, and operational characteristics. Choosing the appropriate distribution system type is a critical decision in water supply engineering, as it affects water quality, pressure maintenance, system redundancy, and overall cost.

Types of Water Distribution Systems

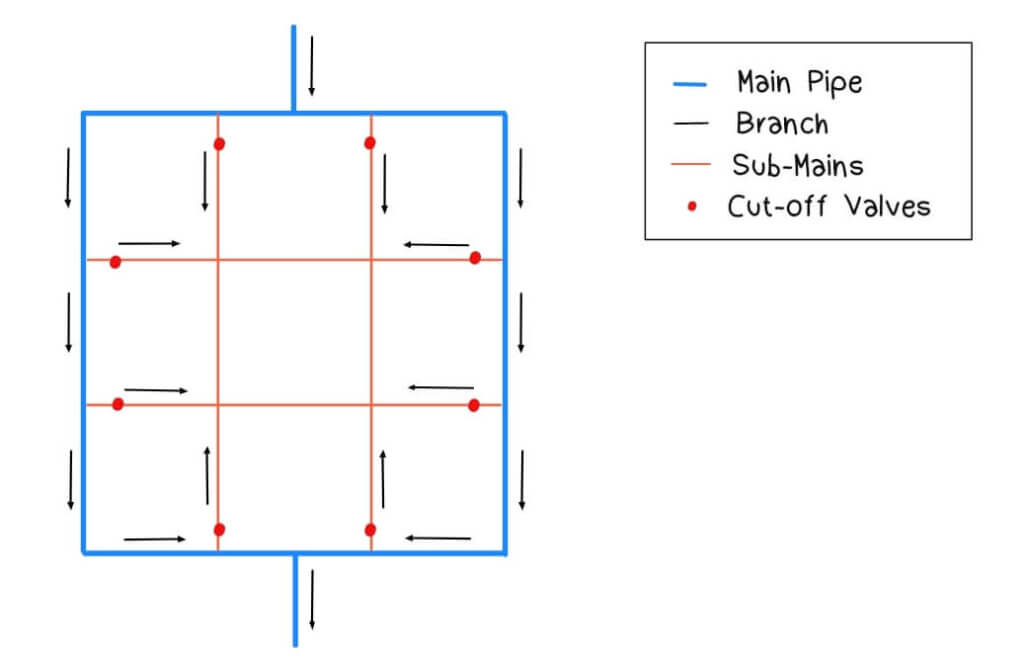

1. Dead End System

1The Dead End System, also known as the Tree System, consists of a main supply line from which sub-mains branch out, and from these sub-mains, smaller branch lines (laterals) extend to serve individual areas. The system resembles a tree structure with a trunk (main), branches (sub-mains), and twigs (service lines). The defining characteristic is that water has only one path to reach any given point, creating terminal points or “dead ends” where water movement ceases.

Advantage

- Simplicity of Installation

– Pipe in this network can be laid easily with straightforward routing. – Less complex construction requirements. - Simple Hydraulic Analysis

– Pressure and discharge can be determined easily and accurately.

– Design calculations are straightforward due to single flow paths. - Economical Pipe Sizing

– Diameters of mains, sub-mains, and branches can be designed specifically for the demand they serve.

– Less cost compared to other systems. - Few Control

– Requires less number of cutoff

– Simpler valve arrangement and maintenance

Disadvantages

- Pressure Variability

– Pressure is not constant throughout the system.

– Very Low Pressure at remote parts and dead ends.

– Service quality deteriorates with distance from source. - Water Stagnation Issues

– Dead ends cause water stagnation when demand is low.

– Stagnation results in sediment deposition.

– Requires more scour valves at dead ends to flush sediments. - Limited Redundancy

– If damage occurs in any branch line, the entire section must be shut down for

– No alternative path for water reach afftected consumers. - Inadequate Fire Protection

– Limited discharge available for firefighting.

– May not meet fire code requirements in many jurisdictions.

Practical Applications

Dead end systems are typically used in:

- Small communities with low population density, it is not best especially if that place has some high-rise building because the water would not suffice.

- Rural areas with scattered development.

- Initial development phase where future expansion can convert to grid system.

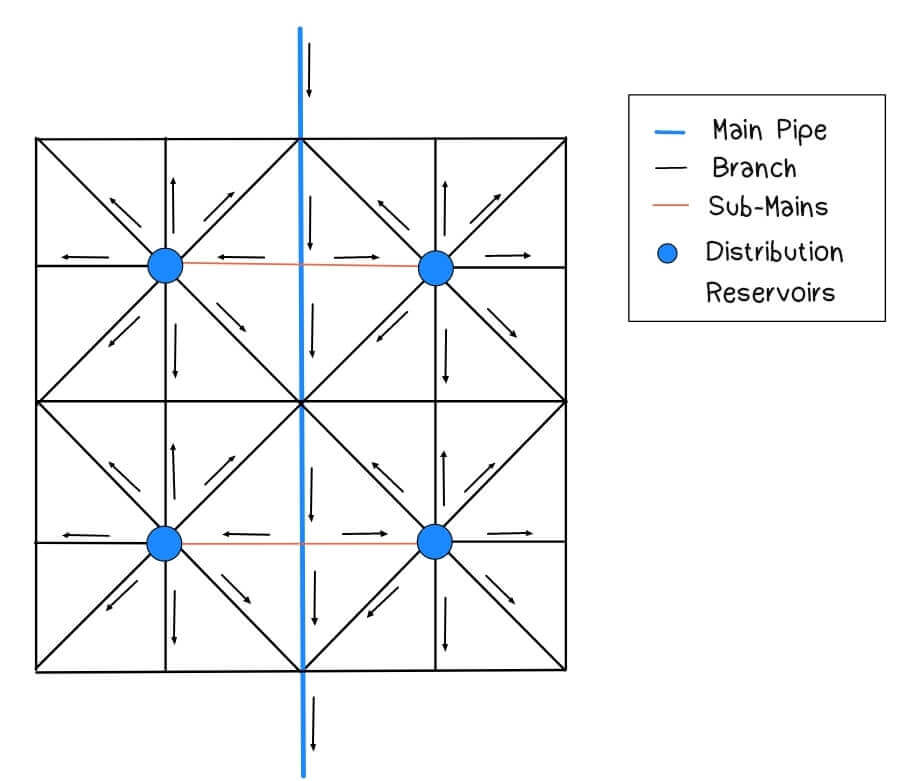

2. Radial System

The Radial System divides the entire service area into several small distribution districts or zones, with an individual reservoir provided for each distribution zone. All distribution reservoirs are connected to a main supply line that typically passes through or near the center of the city or service area. Water radiates outward from the central supply line to the various zone reservoirs, and from each reservoir to its respective service.

Advantages

- Centralized Control with Zone Flexibility

– All distribution reservoirs connect to the main line passing through the city center.

– Allows coordinated management of multiple zones - High Velocity and Pressure

– Water is distributed with high velocity and high pressure from zone reservoirs.

– Shorter distribution distances from zone reservoirs to consumers. - Minimal Head Loss

– Head loss is very small due to quick discharge from nearby reservoirs.

– Efficient hydraulic performance within each zone. - Pressure Zoning Benefits

– Different elevation zones can be served at appropriate pressures.

– Prevents excessive pressure in low-lying areas.

Disadvantages

- High Capital Cost

– Cost of the project is significantly higher due to multiple individual distribution reservoirs

– Each zone requires its own storage facility, land acquisition, and infrastructure - Operational Complexity

– Multiple reservoirs require individual monitoring and maintenance.

– More complex operational management compared to simpler systems - Space Requirements

– Requires suitable sites for multiple reservoirs throughout the service area.

– May be challenging in densely developed urban areas. - Pump and Energy Costs

-May require multiple pumping stations to fill zone reservoirs.

Practical Application

Radial systems are suitable for:

- Large cities with significant topographic variation

- Metropolitan areas requiring pressure zoning

- Communities where centralized storage is impractical

- Areas with distinct service zones or districts

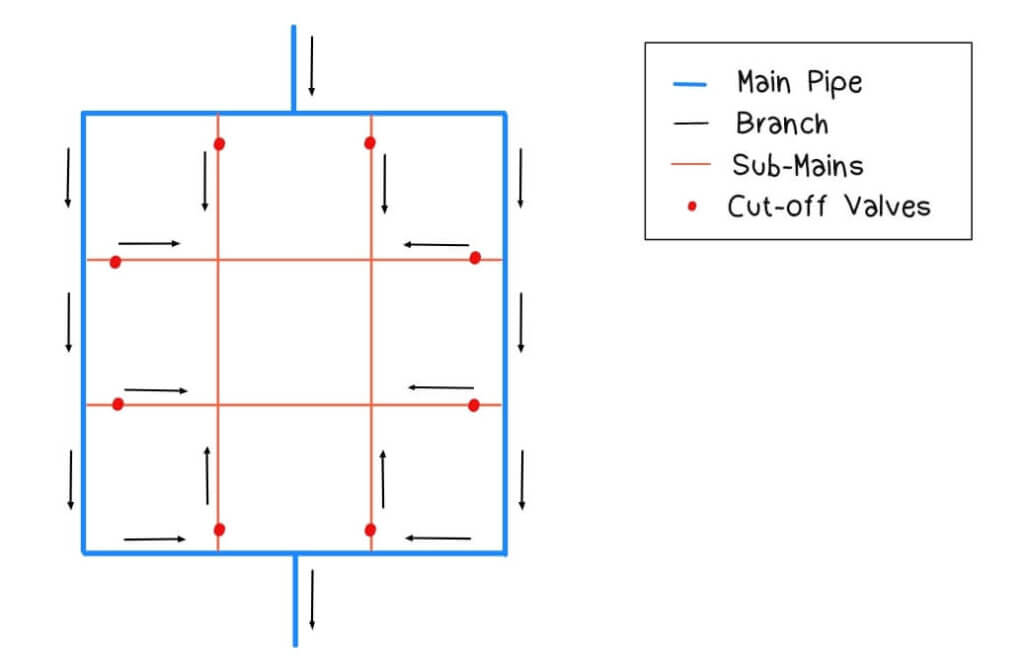

3. Ring System (Circular)

In the Ring System, the entire service area is divided into several distribution zones, with each zone served by a loop or ring of pipes. The main supply line forms a complete loop, and smaller distribution loops branch from it. Within each zone, the pipes are interconnected to form closed circuits or rings, eliminating dead ends while providing multiple paths for water flow.

Advantages

- High Discharge with Minimum Head Loss

– Water is available with higher discharge capacity.

– Minimal head loss due to multiple flow paths.

– Superior hydraulic efficiency. - Ideal for High- Rise Building

- No Water Stagnation

– Continuous circulation eliminates stagnation

– Better water quality maintenance - Maintenance Flexibility

– Repair works can be isolated to specific ring segments.

– Minimal number of consumers affected during maintenance.

Disadvantages

Complex Layout

- More complicated network configuration

- Requires careful hydraulic design

Varied Pipe Requirements

- Different pipe lengths and sizes needed throughout the network

- More complex material procurement and inventory

Longer Total Pipe Length

- Requires longer overall pipe lengths compared to dead end systems

Higher Material Costs

- More extensive piping increases material expenses

- Larger diameter pipes add to costs

Practical Applications

Ring systems are commonly used for:

- Urban areas with high-rise buildings

- Central business districts requiring high reliability

- Industrial zones with large water demands

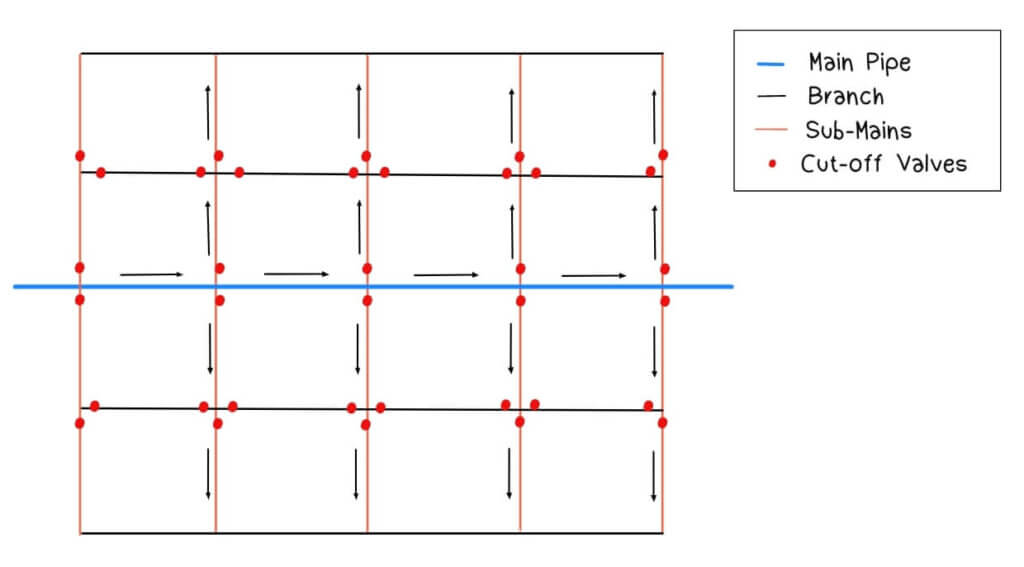

4. Grid Iron System

The Grid Iron System, also known as the Interlaced System or Reticulation System, represents the most advanced and reliable distribution network configuration. In this system, all dead ends are eliminated by interconnecting all supply lines.

Advantages

- Continuous Water Flow

– Water flows continuously without any dead ends.

– Eliminates stagnation and sediment deposition - Minimum Head Loss

– Head loss is minimal due to extensive pipe interconnection.

– Multiple parallel flow paths reduce friction losses.

– Superior hydraulic efficiency across the entire system. - Maintenance Without Service Disruption

– Repair works can be easily accomplished by closing cutoff valves in affected line.

– Alternative flow paths ensure continued service to users.

– Minimal impact on consumers during maintenance operations. - Pressure Stability

-More uniform pressure distribution throughout the network. - System Reliability

– Highest redundancy of all distribution system types.

– Multiple feed paths ensure water supply continuity.

– Excellent resilience to pipe failures or breaks.

Disadvantages

- High Initial Cost

– Most costly system due to extensive interconnections.

– Requires longer total pipe lengths and larger diameters. - Complex Hydraulic Analysis

– Cannot determine accurate discharge, velocity, or pressure in individual pipes using simple methods.

– Requires computer-based network analysis (Hardy Cross method, network solvers). - Extensive Valve Requirements

– More cutoff valves required at intersections.

– Higher valve maintenance and management demands. - Skilled Installation Requirements

– Laying of pipes must be done by skilled workers.

– More complex construction management.

Practical Applications

Grid iron systems are the preferred choice for:

- Modern urban and suburban developments

- Cities with high service reliability requirements

- Commercial and industrial districts

- High-value real estate developments

References:

MeritBrass. (2024). MeritBrass. https://www.meritbrass.com/blog/municipal-water-distribution-system-types

Daily Civil. (2021, October 21). Types Of Water Distribution System. DAILY CIVIL. https://dailycivil.com/types-of-water-distribution-system/