50 Civil Engineering Formulas You Must Know

As a civil engineering student, preparing for exams requires you to apply concepts to a problem, and these formulas will guide you in solving those theoretical and practical problems.

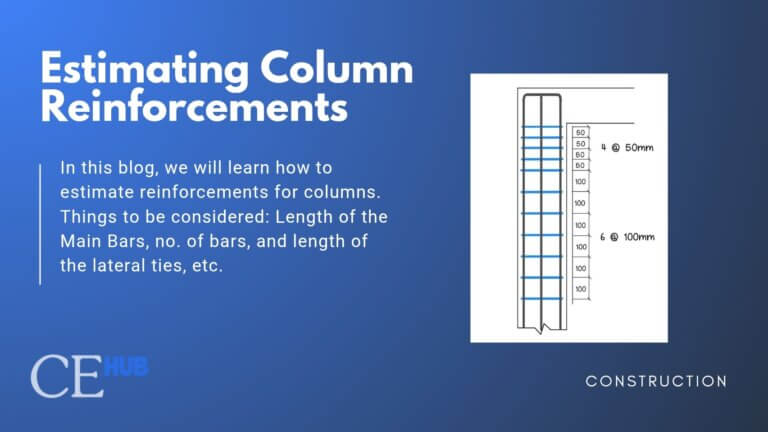

Structural Engineering

Understanding structural behavior is fundamental to designing safe and efficient structures. These formulas help you analyze stresses, deflections, and internal forces in structural elements.

1. Stress

![]()

Where:

- σ = normal stress

- F = applied force

- A = cross-sectional area

This fundamental equation calculates the internal force per unit area within a material, essential for ensuring structural members don’t exceed their strength capacity.

2. Shear Stress in Beams

![]()

Where:

- τ = shear stress

- V = shear force

- Q = first moment of area

- I = moment of inertia

- b = width of section

Used to determine shear stress distribution across a beam’s cross-section, critical for preventing shear failure.

3. Bending Stress

![]()

Where:

- σ = bending stress

- M = bending moment

- y = distance from neutral axis

- I = moment of inertia

Also known as the flexure formula, this calculates stress in beams subjected to bending moments.

4. Moment of Inertia (Rectangular Section)

![]()

Where:

- I = moment of inertia

- b = width

- h = height

Represents resistance to bending for rectangular cross-sections about the centroidal axis.

5. Hooke’s Law

![]()

Where:

- σ = stress

- E = modulus of elasticity

- ε = strain

Describes the linear elastic relationship between stress and strain in materials.

6. Deflection (Simply Supported Beam, Point Load at Center)

δ = PL³/(48EI)

Where:

- δ = maximum deflection

- P = point load

- L = span length

- E = modulus of elasticity

- I = moment of inertia

Essential for serviceability checks in beam design.

7. Euler’s Critical Buckling Load

![]()

Where:

- Pcr = critical buckling load

- E = modulus of elasticity

- I = moment of inertia

- K = effective length factor

- L = actual length

Determines the axial load at which a column will buckle.

8. Shear Force and Bending Moment Relationship

![]()

This differential relationship shows that the slope of the bending moment diagram equals the shear force.

9. Second Moment-Area Theorem

δB/A = ∫(M/EI)x dx

Used to calculate deflections and rotations in beams using the moment diagram.

10. Torsional Shear Stress

![]()

Where:

- τ = shear stress

- T = applied torque

- r = radial distance from center

- J = polar moment of inertia

Calculates stress in circular shafts subjected to torsion.

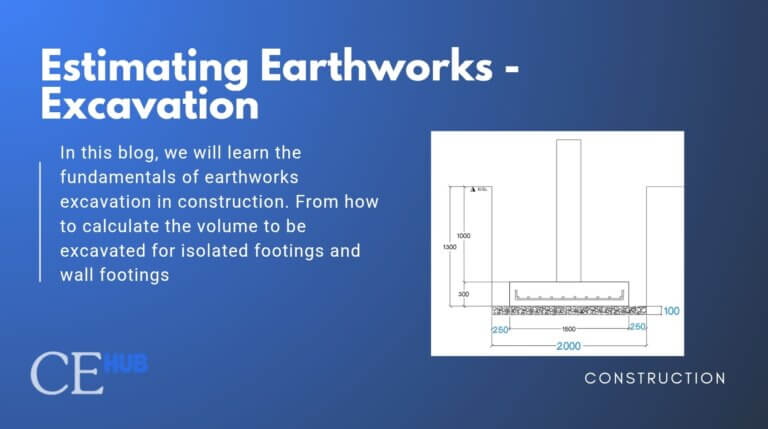

Fluid Mechanics

Fluid mechanics principles are essential for water supply systems, drainage design, and hydraulic structures.

11. Reynolds Number

![]()

Where:

- Fr = Froude number

- v = flow velocity

- g = gravitational acceleration

- L = characteristic length

Characterizes open channel flow as subcritical (Fr < 1), critical (Fr = 1), or supercritical (Fr > 1).

13. Absolute Pressure

![]()

Where:

- Pabs = absolute pressure

- Pgauge = gauge pressure

- Patm = atmospheric pressure

Converts between gauge and absolute pressure measurements.

14. Viscosity

![]()

Where:

- τ = shear stress

- μ = dynamic viscosity

- du/dy = velocity gradient

Defines the relationship between shear stress and velocity gradient in fluids.

15. Hydrostatic Pressure

![]()

Where:

- P = pressure

- ρ = fluid density

- g = gravitational acceleration

- h = depth

Calculates pressure at any depth in a static fluid.

16. Specific Weight of Fluid

![]()

Where:

- γ = specific weight

- ρ = density

- g = gravitational acceleration

- W = weight

- V = volume

Represents weight per unit volume of a fluid.

17. Discharge

![]()

Where:

- Q = volumetric flow rate

- A = cross-sectional area

- v = average velocity

Fundamental equation for calculating flow rate through pipes and channels.

18. Bernoulli’s Equation

![]()

Where:

- P/γ = pressure head

- v²/(2g) = velocity head

- z = elevation head

Conservation of energy equation for fluid flow along a streamline.

19. Darcy-Weisbach Equation

![]()

Where:

- hf = head loss due to friction

- f = friction factor

- L = pipe length

- D = pipe diameter

- v = flow velocity

- g = gravitational acceleration

Calculates head loss in pipes due to friction.

20. Manning’s Equation

![]()

Where:

- V = average velocity

- n = Manning’s roughness coefficient

- R = hydraulic radius

- S = slope of energy grade line

Used for open channel flow calculations.

Concrete and Steel Design

These formulas are crucial for designing reinforced concrete and steel structural members according to modern building codes.

21. Ultimate Moment Capacity of a Singly Reinforced Beam

Mu = φAsfy(d – a/2)

Where:

- Mu = ultimate moment capacity

- φ = strength reduction factor

- As = area of steel reinforcement

- fy = yield strength of steel

- d = effective depth

- a = depth of equivalent stress block

Determines the maximum moment a reinforced concrete beam can resist.

22. Depth of Neutral Axis

![]()

Where:

- c = depth to neutral axis

- a = depth of equivalent stress block

- β₁ = stress block factor (typically 0.85 for normal concrete)

Locates the neutral axis in a reinforced concrete section.

23. Balanced Steel Ratio

Where:

- ρb = balanced steel ratio

- β₁ = stress block factor

- fc’ = concrete compressive strength

- fy = steel yield strength

- εcu = ultimate concrete strain

- εy = steel yield strain

Defines the reinforcement ratio that produces simultaneous crushing of concrete and yielding of steel.

24. Moment of Inertia (Cracked Section)

Where:

- Icr = cracked moment of inertia

- b = width

- c = depth to neutral axis

- n = modular ratio (Es/Ec)

- As = steel area

- d = effective depth

Used for deflection calculations in cracked reinforced concrete sections.

25. LRFD

26. Net Area in Tension

Where:

- An = net area

- Ag = gross area

- Aholes = area of bolt holes

Calculates effective area for tension members accounting for holes.